FIBER OPTIC CABLE PRODUCT

INDOOR CABLE SERIES SM / MM

Zipcord ( F-ZX-XX-XX )

ORDER INFOMATION

| PROPERTIE – High strength aramid yarn strength member ensures high tensile strength and long term stability transmission – Small outer diameter, lightweight, flame retardant, easy to strip, low attenuation, physically soft – Direct splicing between tight buffer cables and need no tie-in box or pigtail | ||||

| APPLICATION – As building to building connecting cable – As indoor soft cable along the wall, ceiling, between layers and in conduits – As pigtails, movable connectors and patch cords for communication equipment – Temperature range -40 oC ~ + 70 oC | ||||

| STANDARD – ANSI/TIA-568-C.3, ANSI/ICEA 596, ANSI/TIA/EIA-568-B.3 ISO/IEC 11801:2002 – Telcordia(Bellcore) GR-409-CORE – ITU-T G.652D (Singlemode), ITU-T G.651 (Multimode), ITU-TG 657A2 – IEC 60332-1, IEC 60332-2& IEC 60332-3, IEC 60793/60794,EIA/TIA-455 – UL Listed E337497 RoHS Compliant 2002/95/EC |

| PRODUCT | PART NUMBER |

| Indoor Cable, Simplex, 50/125MM 1Core | F-Z5-01-SX |

| Indoor Cable, Duplex, 50/125MM 2Core | F-Z5-02-DX |

| Indoor Cable, Simplex, 9/125 SM, 1Core | F-Z9-01-SX |

| Indoor Cable, Duplex, 9/125 SM , 2Core | F-Z9-02-DX |

| PACKING AND DRUM The cable is rounded on a non-returnable wooden drum. Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture. The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter. – Cable type and number of optical fiber – Manufacturer name – Month and Year of Manufacture – Cable length The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1% |

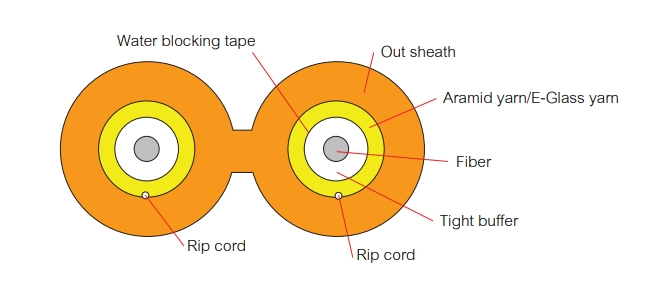

CONSTRUCTION

OPTICAL FIBERCHARACTERISTICS

CONSTRUCTION

| Fiber type | Single mode | Multi-mode | ||||||

| 9/125 µm (OS2) | 62.5/125 µm (OM1) | 50/125 µm (OM2) | 50/125 µm (OM3) | 50/125 µm (OM4) | ||||

| Core Diameter (µm) | 9 | 62.5 | 50 | 50 | 50 | |||

| Cladding diameter (µm) | 125 | |||||||

| Coating diameter (µm) | 250 | |||||||

| Buffer diameter (µm) | 900 | |||||||

| Fiber count | 2 | |||||||

| Outer Diameter D*H (mm) | 1.6*3.3 | 1.6*3.3 | 1.8*3.7 | 2.0*4.1 | 2.8*5.7 | |||

| Nominal weight (kg/km) | 5.7 | 5.7 | 6.2 | 8.2 | 13.2 | |||

| Tight buffered fiber | Material Thickness | Polyvinyl chloride 0.33 | (PVC) | |||||

| Strength member | Aramid yarn | |||||||

| Sheath | Material Thickness | Polyvinyl chloride 0.5-0.8 | (PVC) | |||||

| Max tensile strength (N) | Short term | 160 | 160 | 160 | 200 | 300 | ||

| Long term | 80 | 80 | 80 | 100 | 160 | |||

| Min bending radius Static | Dynamic Static | 20H 10H | ||||||

| Max crush radius (n/100nm) | 1000 | |||||||

OPTICAL FIBERCHARACTERISTICS

| Attenuation | 850nm | ≤23 ≤25 ≤27 | [dB/km] |

| 1300nm | ≤0.55≤0.70≤0.80 | [dB/km] | |

| Overfilled modal bandwidth | 850nm | ≥500≥400≥400 | [MHz-km] |

| 1300nm | ≥1000≥800≥800 | [MHz-km] | |

| Numerical aperture (NA) | 0.200 ±1.015 | ||

| Group index of refraction (typical) | 850nm | 1.482 | |

| Backscatter characteristics | 1300nm | ||

| Step (mean of bidirectional measurement) | ≤0.10 | [dB] | |

| Irregularities over fiber length and point discontinuity | ≤0.10 | [dB] | |

| Different backscatter coefficient (bidirectional measurement) | ≤0.08 | [dB/km] | |

| Core diameter | 50±2.5 | [µm] | |

| Cladding diameter | 12.50±1.0 | [µm] | |

| Cladding non-circularity | ≤0.10 | [µm] | |

| Coating diameter | 242±7 | [µm] | |

| Coating/cladding concentricity error | ≤12.0 | [%] | |

| Coating non-circularity | ≤6.0 | [µm] | |

| Core/cladding concentricity error | ≤1.5 | [dB/km] | |

| Environmental characteristics | 850nm, 1300nm | [dB/km] | |

| Temperature dependence,induced attenuation | -60 *C -+85*C | ≤0.10 | [dB/km] |

| Temperature-humidity cycling,induced attenuation | -10C-+85*C.90% R.H | ≤0.20 | [dB/km] |

| Damp heat dependence,induced attenuation | 85*C.85% R.H 30 days | ≤0.20 | [dB/km] |

| Water soak dependence , induced attenuation | 20 ‘C,30 days | ≤0.20 | [dB/km] |