FIBER OPTIC CABLE PRODUCT

SINGLE TUBE, INDOOR/OUTDOOR CABLE SM/MM

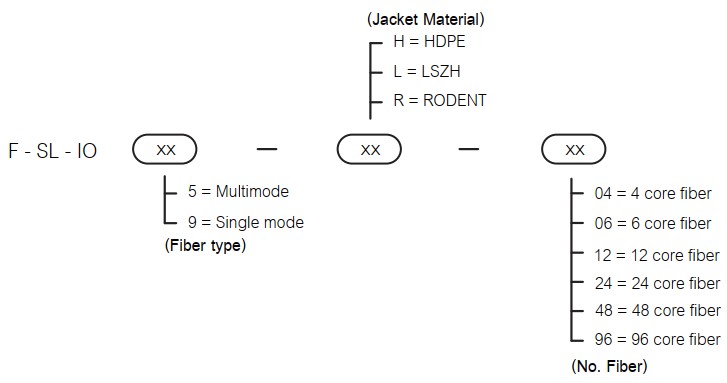

F-SL-IOXX-XX-XX

ORDER INFOMATION

| PRODUCT DESCRIPTION | ||

| – Low attenuation, dispersion and special control of excess fiber length ensure excellent mechanical and envelopment properties. | ||

| – Filling compound and water block material validly prevent water penetration. | ||

| APPLICATION | ||

| – Optical transmission cables for transmission equipment, data processing equipment also suitable for general cabling. | ||

| – Laying method : Conduit, aerial, direct buried, shelf | ||

| – Temperature range -40 oC – +70 oC | ||

| STANDARD | ||

| – ATM, FDDI, FTTX, Fiber Channel,CATV, Communication | ||

| – ISO/IEC 11801:2007, ISO/IEC 11801:2011(Ed.2.2) | ||

| – ANSI/TIA/EIA-568-B.3, ANSI/ TIA-568-C.3, ANSI/TIA-568.3-D, ANSI/ICEA 640 | ||

| – Telcordia(Bellcore)GR-20CORE, GR-409-CORE | ||

| – ANSI/ICEA 596, ICEA696, IEC61034-2, IEC60754-2, IEC60793, IEC60794-1-2 | ||

| – ITU G.652D, ITU-TG 657A2 | ||

| – TIA/EIA-598-C (Rev.TIA/EIA-598-A), EIA-359-A. | ||

| – IEEE802.3z, IEEE802.3ae, IEEE802.3 (LAN, Ethernet Fast Ethernet, | ||

| Gigabit Ethernet and 10 Gigabit Ethernet 40-100 Gbps) | ||

| – RoHS compliant | ||

| – TISI-2165 | ||

| – Made in Thailand : MiT | ||

| PACKING AND DRUM The cable is rounded on a non-returnable wooden drum. Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture. The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter. – Cable type and number of optical fiber – Manufacturer name – Month and Year of Manufacture – Cable length The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1% |

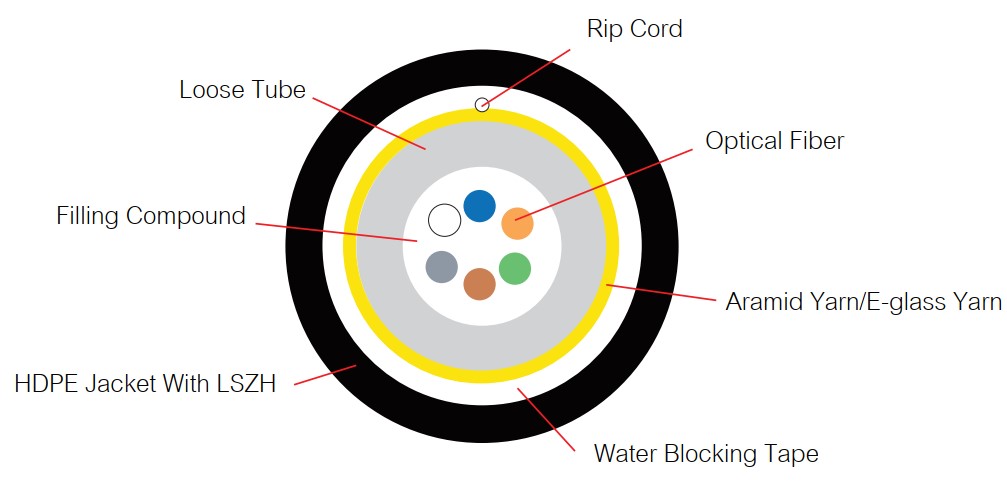

CONSTRUCTION

OPTICAL FIBERCHARACTERISTICS

TEST REQUIREMENTS

OPTICAL CHARACTERISTICS

CONSTRUCTION

| Structure | Parameter | |

| Fiber count | Fibers | 6/12 |

| Loose tube | Material | PBT ,(Thixotropic Jelly compound) |

| No. fiber per tube | 6/12 | |

| Diameter | Approx. 2.5 | |

| Water blocking tape | NWF 0.3mm | |

| Rip cord | PEY | |

| Strength member | Material | Aramid yarn/E-Glass yarn |

| Cable sheath | Material | HDPE withLSZH 1.6±0.2mm, withRodent Repellent (LS2) |

| Core Diameter (µm) | Single mode / Multi mode | Single mode 9 / Multi mode 50 |

| Cladding Diameter (µm) | 9/125 µm (OS2) | 125 |

| Coating Diameter (µm) | 250 | |

| Cable diameter overall | Approx.4.5 | |

| Cable Weight | Approx.9.6±1.0 | |

| Max tensile strength (N) | Short term | 2700 N |

| Long term | 600 N | |

| Max crush resistance (N/100mm) | Short term | 2000 N |

| Long term | 1000 N | |

| Min bending radius | Dynamic | 15D |

| Static | 10D | |

| Operation Temperate | Storage | -20-+75°C |

| Installation | -40-+80°C | |

| Rip Cord | Material | Polyester cords |

OPTICAL FIBERCHARACTERISTICS

| CATEGORY | DESCRIPTION | SPECIFICATIONS |

| Optical Specifications | ITU-T G.652D(SinglemodeOS2) 9/125 µm (OS2) | |

| ITU-T G651(Multimode) | ||

| 62.5/125 µm , 50/125 µm | ||

| Attenuation | @1310nm | ≤0.35/≤0.33dB/km |

| @1383nm | ≤0.35/≤0.31dB/km | |

| @1490nm | ≤0.24db/km | |

| @1550nm | ≤0.21/≤0.19dB/km | |

| @1625nm | ≤0.23/≤0.20dB/km | |

| Attenuation discontinuity | ≤0.05 dB | |

| Attenuation vs. Wavelength | 1285 -1330 @1310nm | ≤0.05 dB/km |

| 1525 -1575@1550nm | ≤0.05 dB/km | |

| Zero dispersion wavelength | 1300 -1324 nm | |

| Zero dispersion slope | ≤0. 092 ps/(nm².km) | |

| Dispersion | @1310nm | ≤3.5 ps/nm.km |

| @1550nm | ≤18 ps/nm.km | |

| Polarization mode dispersion(PMD) | ≤0.2 ps/km ½ | |

| Cable cutoff wavelength (λcc ) | ≤1260 nm | |

| Effective group index of reaction | @1310nm | 1.4675 |

| @1550nm | 1.4681 | |

| Geometric Specifications | ||

| Modefield diameter | @1310nm | 9.2 ± 0.6 µm |

| @1550nm | 10.4 ± 0.8 µm | |

| Cladding diameter | 125 ± 1 µm | |

| Cladding non -circularity | ≤1.0 % | |

| Coating Material | Material | UV curable acrylate |

| Diameter | 250± 5µm | |

| Coating/Cladding concentricity error | ≤12 µm | |

| Core/Cladding concentricity error | ≤0.5µm | |

| Color Fiber Diameter | 250 µm ± 15 µm (Colored) | |

| Fiber proof-tested | 0.69GPa( 1.0%, 100kpsi) in accordancewiththeoptical fiber proof test by IEC 60793-1-30 |

TEST REQUIREMENTS

| Item | Method | Acceptance criteria |

| Tensile test | – Max. tensilestrength: 1200N | -Fiber strain at maximum |

| IEC 60794-1-2-E1A | – Samplelength: 50meters | -Load max. 0.33 % |

| TIA/EIA-455-33A | – Times: 1 hour | -Attenuation increase ≤ 0.1dB |

| Crushor Compression test | – Load: 500N | -No splits or cracks in the outer jacket |

| IEC 60794-1-2-E3 | – Time: 10 minutes | -Attenuation increase ≤ 0.10 dB |

| TIA/EIA-455-41A | – Length: 100 mm | |

| Impact test | – Impact energy: 450 g | – No splits or cracks in the outer jacket |

| IEC 60794-1-2-E4 | – Height: 1 meter | -Attenuation increase ≤ 0.10 dB (after the test) |

| TIA/EIA-455-25C | – Impact points: min.1 | |

| – Number of impacts: 5 | ||

| Torsionor Twist test IEC 60794-1-2-E7 | – 1 m cable length with 150 N weight – ±180° ,10 cycles | – No splits or cracks in the outer jacket -Attenuation increase ≤ 0.10 dB (after the test) |

| TIA/EIA-455-85A | ||

| Repeated bending Cable bending Test | – Radius = 20 × cable outer diameter – 1m cable length with 150 N weight, 30 cycles | – No splits or cracks in the outer jacket -Attenuation increase ≤ 0.10 dB (after the test) |

| IEC 60794-1-2-E6, TIA/EIA-455-104A | ||

| IEC 60794-1-2-E11B | ||

| Temperature cycling test | – Temperaturestep: +20 oC -40 oC+70 oC-40 oC | -Attenuation variation for reference |

| IEC 60794-1-2-F1 | +70 oC+20 oC | value(the attenuation to be measured before |

| TIA/EIA-455-3A | – Timeper eachstep: 16hrs. | test at +20±3 ) ≤0.10dB/km |

| – Number of cycles: 2cycles | ||

| Water penetration test | – Water height: 1m | -No water leakage at the end of the sample |

| IEC 60794-1-2-F5 | – Sample length:3m | |

| TIA/EIA-455-82B | – Duration of test: 24hrs | |

| Drip test | – Five 0.3m samples suspended vertically in a climate | -No filling compound shall drip from tubes after 24 hrs. |

| IEC 60794-1-2-E14 | chamber, raised temperature to +70oC | |

OPTICAL CHARACTERISTICS

| Optical Transmission Performance | Single Mode | Multi Mode | |||

| 1310/1383/1550/1625 nm | 850/1300 nm | ||||

| 9/125 µm (OS2) | 62.5/125 µm (OS1) | 50/125 µm(OS2) | 50/125 µm (OS3) | 50/125 µm (OS4) | |

| Max Attenuation (dN/km) | 0.35/0.35/0.21/0.23 | 3.0/0.8 | 2.7/0.8 | 2.7/0.8 | 2.7/0.8 |

| Type Attenuation (dN/km) | 0.33/0.31/0.19/0.20 | 2.7/0.6 | 2.5/0.7 | 2.3/0.6 | 2.3/0.6 |

| Bandwidth (MHz/km) | N/A | 200/600 | 500/500 | 1500/500 | 3500/500 |

| 850nm Laser bandwidth (MHz/km) | N/A | N/A | N/A | 2000 | 4700 |

| Numerical | 0.13 ± 0.01 | 0.275 ± 0.015 | 0.200 ± 0.015 | 0.200 ± 0.015 | 0.200 ± 0.015 |